-

Gat No 611 , Mouje-Kuruli, MIDC Chakan, Tal-khed Pune - 410501

Email Id - uday@excelplants.com

CallUs - +91-9225776611

OUR PRODUCTS - Industrial Heat Exchangers

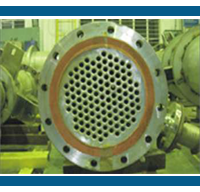

Excel plants is the leader design, manufacturing and supplier of Heat exchange equipments. Our heat exchangers provide fast and Effective heat transfer rate. We Specialized in Heat Exchanger solutions and leading Heat Exchanger Manufacturer in India. Shell & tube type Heat exchangers are having two divisions one is shell and other is Tubes. Here One fluid runs through the tubes, and another fluid flows over the tubes (through the shell) to transfer heat between the two fluids. For this purpose seamless/ERW or Rolled pipes are used for shell. And Seamless tubes are used for Tubes.

⇓ Applications of Shell and Tube Heat Exchangers

1. Power Plants Condensers, Pre Heaters, Waste water treatment.

1. Power Plants Condensers, Pre Heaters, Waste water treatment.

2. Oil Refineries Inter cooling Purpose, Re Processing Purpose.

3. Manufacturing Industries Oil coolers for Quenching Oil, Oil coolers for Lubrication Oil

4. Offshore Industry Water Makers

5. Condensers

6. Food and Dairy Industries

7. Refrigeration Systems

8. Chemical industries

9. Pulp and Paper Industries

10. Wine-brewery industry

11. Plastic and Fertilizers Industries.

A shell and tube heat exchanger is a class of heat exchanger designs. It is the most common type of heat exchanger in oil refineries and other large chemical processes, and is suited for higher-pressure applications.

As its name implies, this type of heat exchanger consists of a shell (a large vessel) with a bundle of tubes inside it. One fluid runs through the tubes, and the second runs over the tubes (through the shell) to transfer heat between the two fluids.

The set of tubes is called a tube bundle, and may be composed by several types of tubes: plain, longitudinally finned, etc.